Automatic filters

Features & benefits

Features & benefits

- Due to the low pressure required for backflushing (>2.0Bar), the customer can save energy costs by reducing the size of the irrigation pump.

- The system is portable, pre-assembled, light-weight and requires a small footprint, saving time and money in terms of transportation and installation.

- The system is made from composed plastic materials, designed for chemical resistance and featuring a minimum of moving parts, ensuring lower maintenance and longevity.

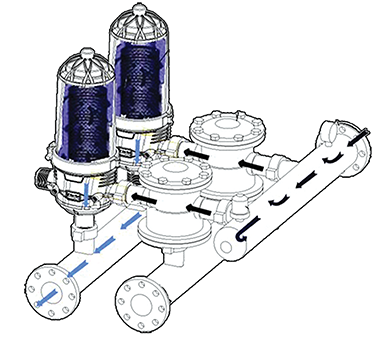

Filtration mode

Filtration mode

The disc is held tightly together, allowing the irrigation water to pass through the micron water passages between the disc and debris

traps.

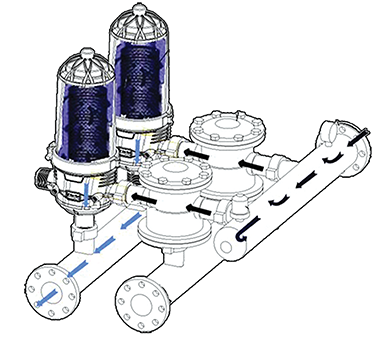

Backflush mode

Backflush mode

The Backflush process initiated by time or by a differential pressure switch which measures the pressure before and after the filter. The pressure differential results from debris accumulated on the disc. The filter’s controller sends a command to a 3-way valve to change the flow direction through the filter element. The opposite flow decompresses the stacked discs and jets of water will spin the discs and flush all the trapped debris down the drain. This process is done for each filter in the system.

Filtron grade for our

| Micron | 50µ | 80µ | 100µ | 130µ | 180µ | 420µ |

| Mesh | 300 | 200 | 150 | 120 | 80 | 40 |

| Disc Color |